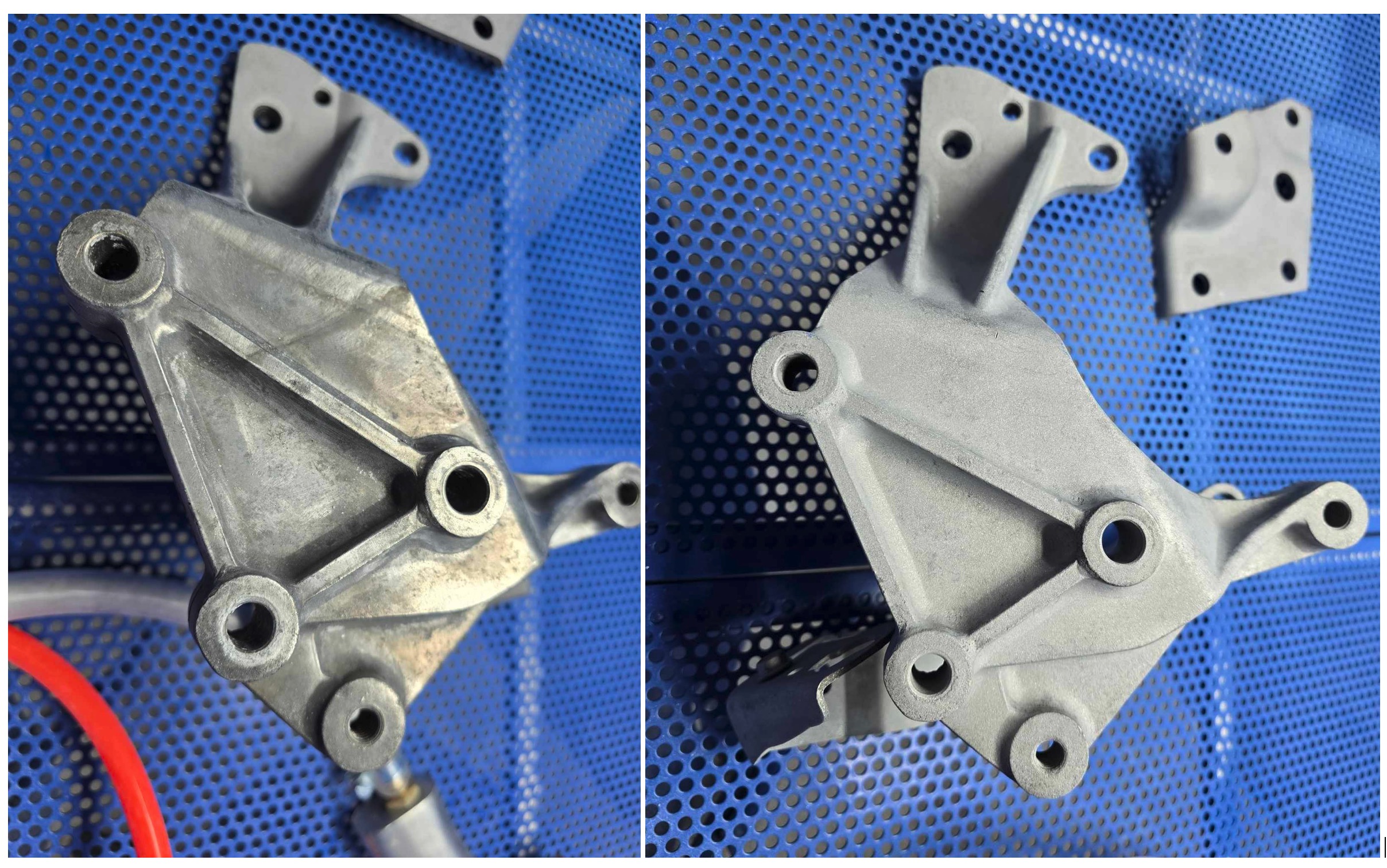

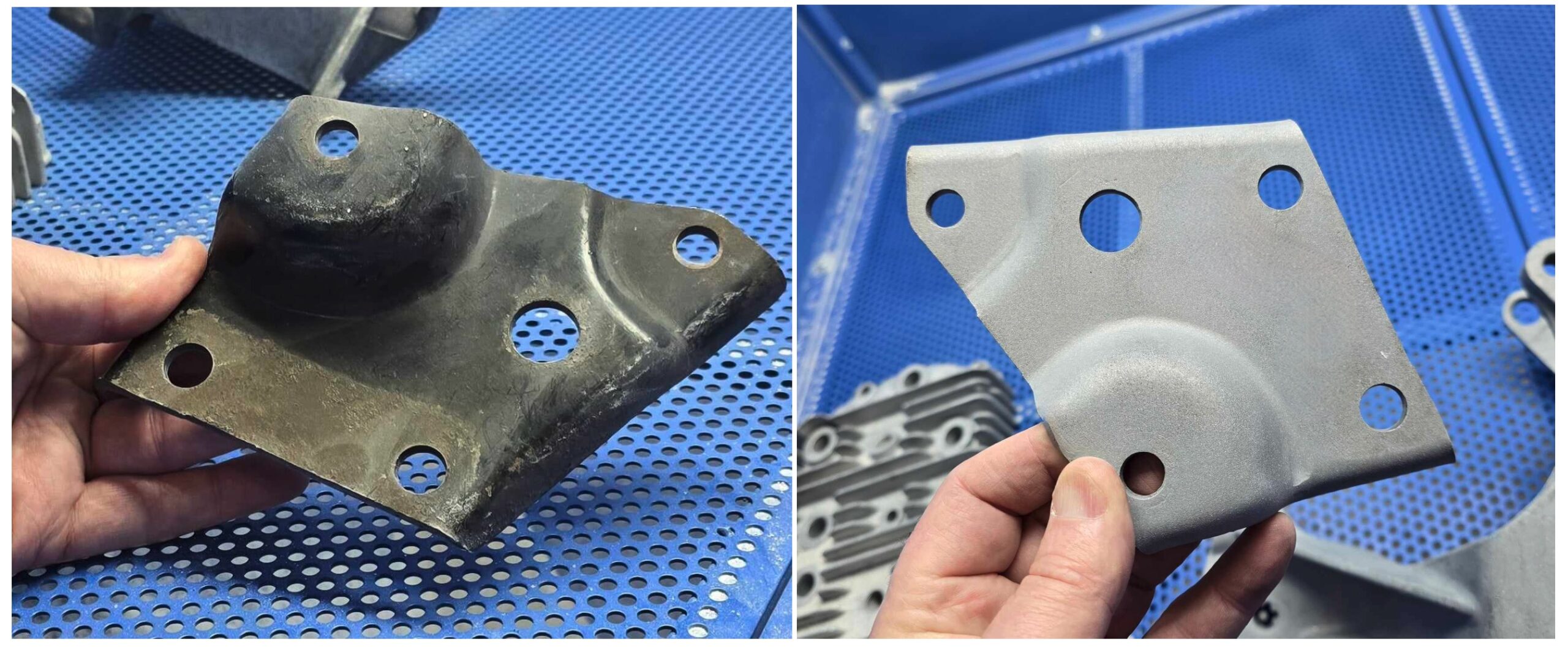

Imagine your precious engine or antique pieces being brought back to their original state – or BETTER than – splendor!

VAPOUR BLASTING

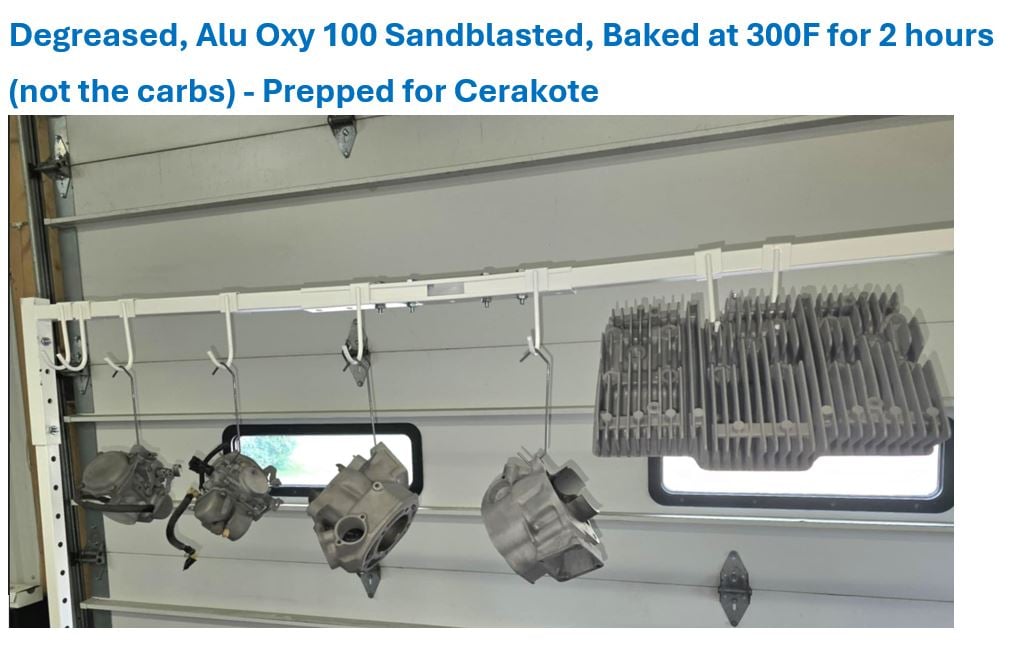

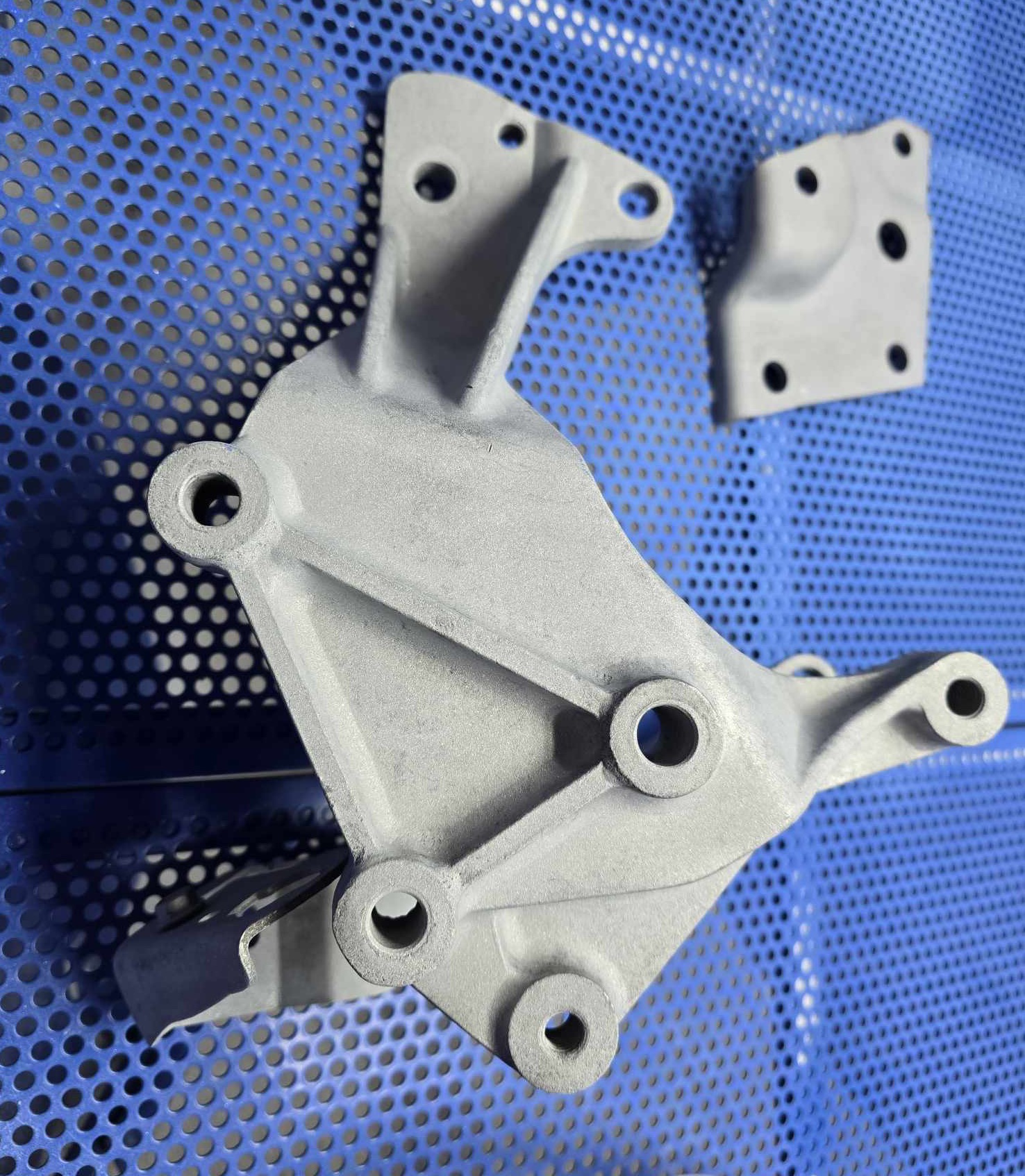

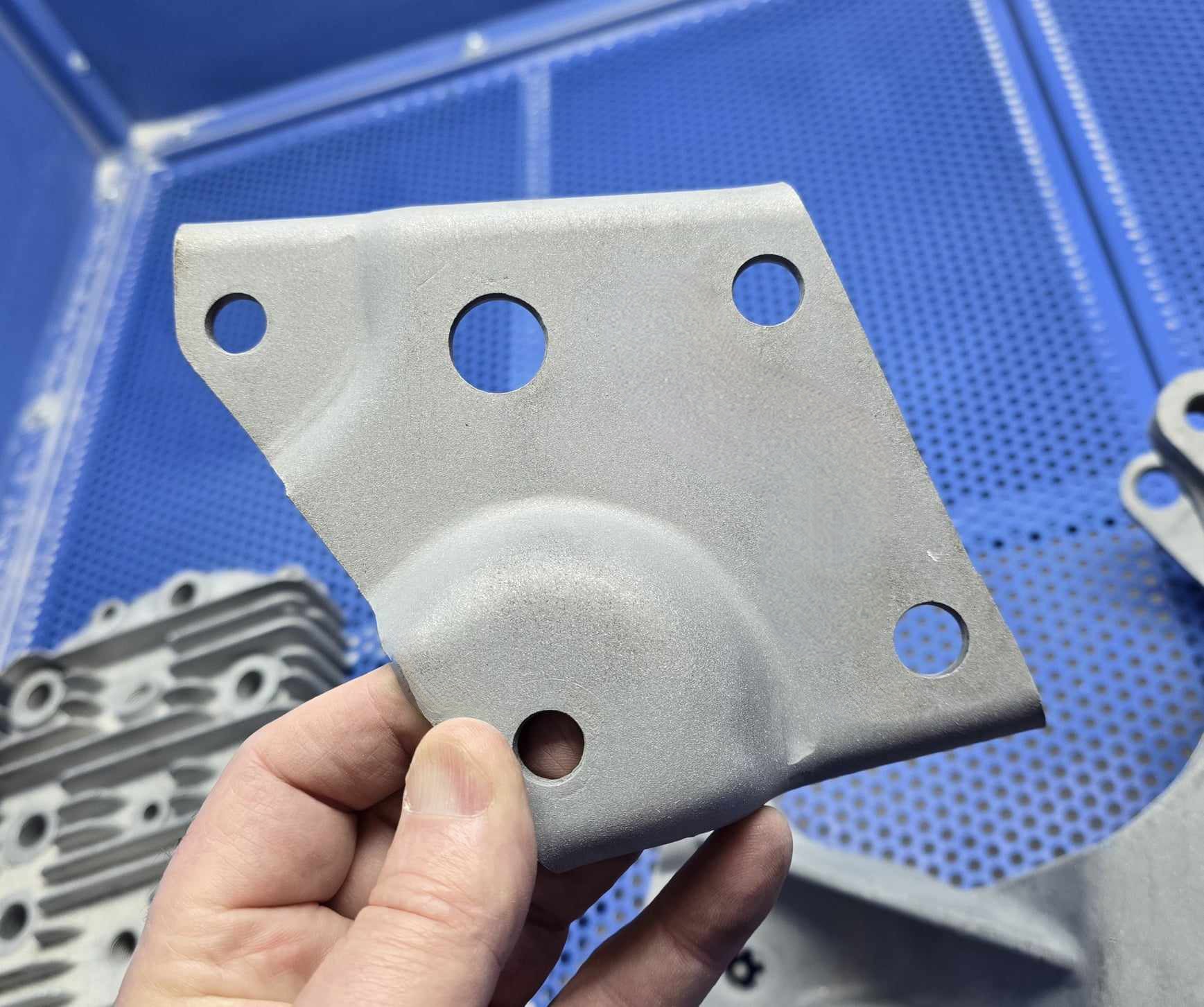

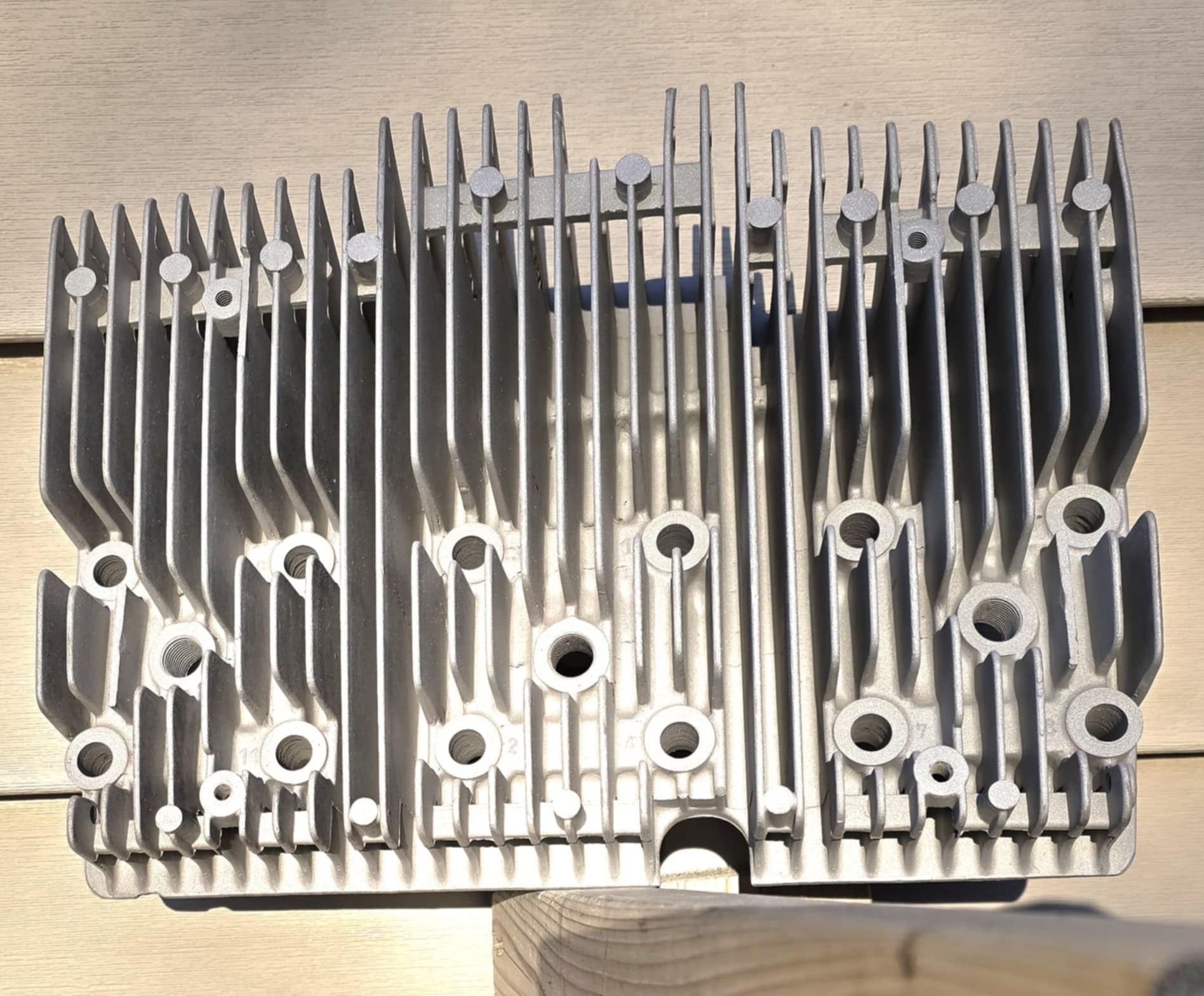

- We use vapour blasting, regular grit and fine dry sand blasting depending on your needs and budget.

- Vapour blasting is a non-aggressive surface prep technique that has been specifically developed for applications requiring finer finishes. Combining a thin film of water with fine blasting media, this technique can remove dirt, contaminants, rust, and corrosion.

- The Result: A clean, satin, closed finish that is less prone to oxidation than dry-blasted parts. SMALL PARTS – Ideal for engine components (e.g., carburetors, manifolds, motorcycle casings), vintage tools, and small brackets.

CERAKOTE

- The various CERAKOTE® series address specific client requirements.The C series can be air dried and cured and the coating can tolerate temperatures up to 2,200 °F.

- The E series and F series offer more colour choices and have different specifications and also require heat curing. Our oven can take pieces up to 22″ wide x 18″ deep x 14″ high.

- Explore all CERAKOTE® series here or contact us and let us help you according to your needs.